GOOD THINGS 2: PASTA DI GRAGNANO

19.08.2014 BEST OF THE COAST

Once Minori, on the Amalfi Coast, was famous for its pasta production, but today the mantle has passed to Gragnano, on the other side of the jagged Monti Lattari mountains. At first sight it’s an unassuming place, its suburbs a sprawl of post-war apartment blocks, but as you approach the centro storico, churches and older palazzi testify to its strategic importance as a trait d’union between the fertile Sarno plain and the dairy-farming uplands around Agerola.

Pasta has been made in Gragnano for at least four centuries, and wheat was grown here long before that. In fact the town’s name likely derives from the Latin term Praedium Granum – a large tract of land given over to wheat cultivation. In addition to wheat, the town had two things going for it that sealed its vocation for pasta making: wind and water.

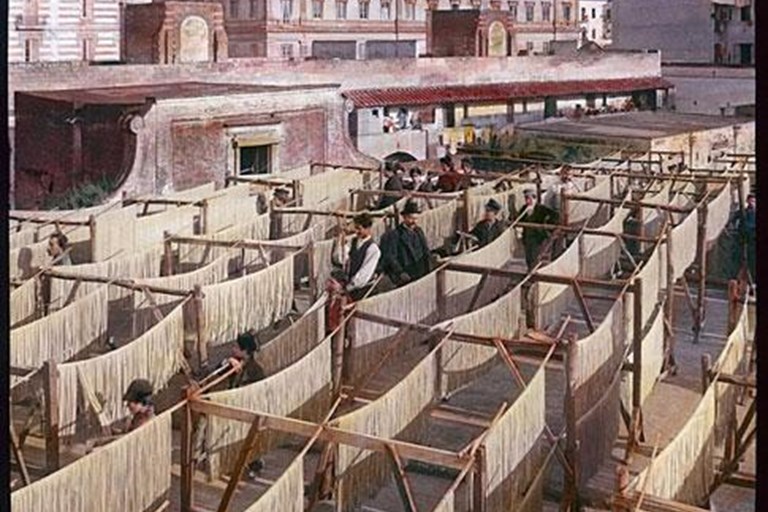

A steady breeze blows down off the Lattari mountains all day long, summer and winter. Graganano’s main street, Via Roma, where pasta strands were once hung out to dry, was designed to channel this breeze and to receive the sun from morning to evening. And the water that surges down towards the town from a high mountain spring is clear and fresh: locals still collect it from the municipal fountain to drink at home and use for cooking.

In 1860 there were 80 pastifici or pasta-making factories in Gragnano. Today there are just a handful, but although it has become a niche product, pasta di Gragnano is still much sought after by chefs and gourmets the world over. One of the best of the current crop of Gragnano artisanal pasta manufacturers is Gerardo di Nola. It’s owned and run by the larger-than-life Giovanni Assante, who worked for the company for 22 years under its previous owners, then invested all his savings to buy it when they decided to sell up.

Today the durum wheat that goes into Giovanni’s pasta comes from the fertile plains around Casalbore, near Avellino, and drying takes place in huge ovens at a constant temperature of 50°C. But little else has changed in the production process since the nineteenth century: the water used to make the impasto, or dough, is the same mountain spring water that has always been used and the pasta shapes are still extruded through bronze dies that come in a myriad of different forms – thirty, to be exact, from eliche (spirals) to orecchiette (literally ‘little ears’). A whole cycle takes 24 hours and produces around 1,000 kilos of pasta – after which the dies are changed and a new shape is put through the mill.

View

From the modest factory – really just a small, barrel-vaulted room with three workers, who labour at times in temperatures of over 40 degrees – Gerardo di Nola pasta finds its way to some of Italy’s leading restaurants, from Massimo Bottura’s Osteria Francescana in Modena to Le Sirenuse’s own La Sponda. It’s a fitting tribute to the passion of Giovanni Assante and his team – and to the excellence of their raw materials.

Le Sirenuse Newsletter

Stay up to date

Sign up to our newsletter for regular updates on Amalfi Coast stories, events, recipes and glorious sunsets